Alpha Descaler Try it risk free and see the difference for your needs.

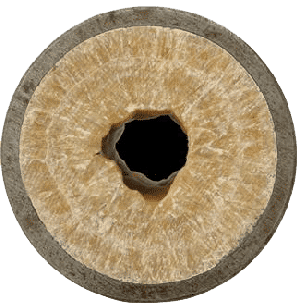

BEFORE

AFTER

We’re expanding our services to include quick and seamless shipping

for Alpha Descaler for all our clients in the US!

Now, fulfilling orders is easier and more efficient than ever.

Get Your Free Sample Today !

Alpha Descaler : Environmentally Safe Industrial Solution

QUICK LINKS to SDS, corrosion tests, spec sheet

Alpha Descaler FG and the more powerful Alpha Descaler FG Extra Strength will work on most applications and is also NSF /ANSI / CAN 60 approved and considered food grade.

Regular Alpha Descaler and the stronger Alpha Descaler Extra Strength is used if the system is contaminated extensively with other particulate such as silica, oil, etc. in addition to the scale such as may be found in power plants and therefore has extra ingredients added to assist cleaning.

To assist you in your scheduled maintenance program, we can provide an email reminder. Register Here

Apply to join our referral program and earn up to 15% Apply Here

NO MORE !

Hydrochloric, Phosphoric, Sulfonic

and Other Mineral ACIDS

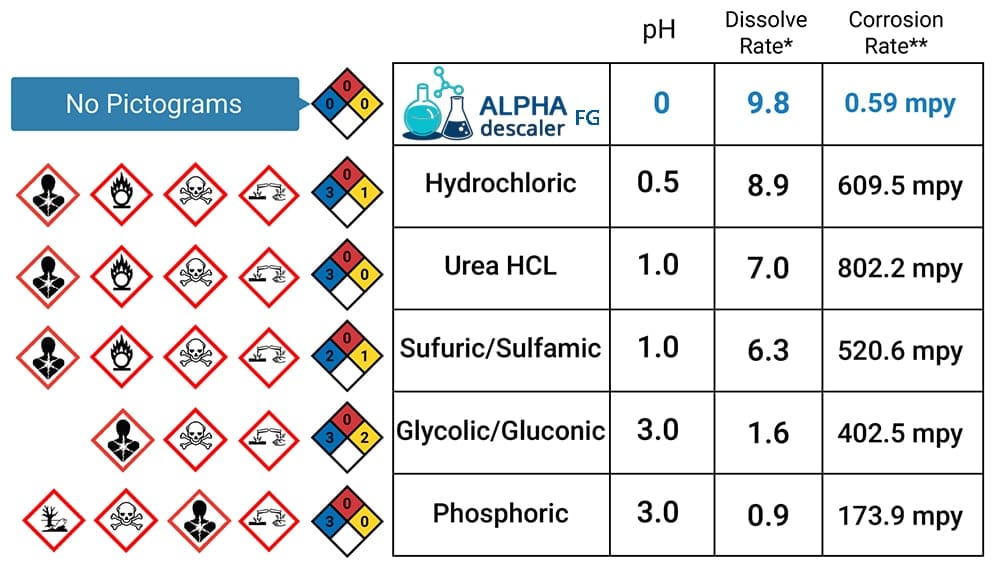

TRULY NON-CORROSIVE

to Skin, Eye and Metals

STRONG & FAST

But SAFE, NON-TOXIC & NON-CORROSIVE & BIODEGRADABLE

**Tests were done on 1020 Carbon Steel. Non-D.O.T. Regulated/Non-D.O.T. Hazardous EXEMPT as per 49 CFR 173.154(d) (1) <6.25 mmpy.

D. O. T. classifies a material to be corrosive and hazardous if it has a corrosion rate that exceeds 6.25 mmpy on SAE C1020 carbon steel or 7075-Y6 Aluminum.

Biodegradable.

100% Biodegradable in 10 days. Safe to the environment.

Safe

Won’t harm workers when used as directed. Considered non-fuming, and non-corrosive to personnel and to materials. Non-toxic.

Economical.

Comparing all costs to other products and cleaning options and shipping/handling and disposal costs due to personnel and environmental safety. Considered non-hazardous to ship and no hazard signs necessary.

Fast.

Equipment is cleaned in a few hours due to consistent descaling action and extremely low foaming.

Not Corrosive

Lowest corrosion rate of any descaler whether it is HCl phosphoric, sulfamic, etc. Alpha Descaler is safe on all materials found in water operated equipment including stainless steel.

Powerful detergents

and penetrating agents in Alpha Descaler to clean other materials mixed with the scale.

USA orders: Ship or Pick up from 701 West Chippewa Avenue, South Bend, IN 46614

Canada orders: Ship or Pick up from: 2828 Slough Street Mississauga, ON, L4T 1G3 or 3258 Marentette Avenue Windsor, ON, N9X 4G4. (Stock available also in Alberta)

Asia and SE Asia orders: Shipped from Bangkok, Thailand

Other countries: Contact us

INDUSTRIES

Below are some industries and applications where Alpha Descaler can be used including the Chemical Industry, Marine Industry, General Manufacturing, Wastewater just to name a few. See full list below.

- Air Compressors

- Boilers

- Closed Circuit Cooling

- Cooling Towers

- Dynamometers

- Extruders

- Heat Exchangers

- Molders

- Radiators

- Water heaters

- Welders

- Air Compressors

- Boilers

- CHT Systems

- Condensers

- Cooling Towers

- Distilling Units

- Engine Cooling Systems

- Evaporators

- Heat Exchangers

- Jet blast deflectors

- Air Compressors

- Boilers

- CO2 Generators

- Cooling Towers

- Heat Exchangers

- Heaters

- Rinse Tanks

- Sterilizers and Washers

- Air Compressors

- Ball Mills

- Boilers

- CO2 Generators

- Cooling Towers

- Heat Exchangers

- Heaters

- Rinse Tanks

- Sterilizers and Washers

- Air Compressors

- Boilers

- Cooling Towers

- Demisters

- Dryers

- Extruders

- Kettles

- Mixers

- Reactors

- Scrubbers

- Vacuum Pumps

- Air Compressors

- Boilers

- Condensers

- Cooling Towers

- Heat Exchangers

- Ice Machines

- Kathabar Units

- Refrigeration Equipment

- Steam Tables

- Air Compressors

- Boilers

- Chillers

- Cooling Towers

- Furnaces

- Heat Exchangers

- Quenchers

- Vacuum Pumps

- Water Heaters

- Air Compressors

- Boilers

- Chillers

- Cooling Towers

- Furnaces

- Quenchers

- Vacuum Pumps

- Water Heaters

- Absorption units

- Ammonia Compressors

- Cooling Towers

- Condensers

- Centrifugal chillers

- Heat Exchangers

- Boilers

- Bow Thruster

- CHT Systems

- Chillers

- Condensors

- Heat Exchangers

- Manifolds

- Oil Coolers

- Water Heaters

- Air Compressors

- Ball Mills

- Bearings

- Boilers

- Conveyers

- Cooling Towers

- Filters

- Presses

- Process Lines

- Radiators

- Water heaters

- Air Compressors

- Boilers

- Cooling Towers

- Demisters

- Heat Exchangers

- Loop Systems

- Kathabars

- Pumps

- Reactors

- Stills

- Sterilizers

- Air Compressors

- Boilers

- Chill Rolls

- Cooling Towers

- Extruders

- Heat Exchangers

- Injection Molding Machines

- Molds

- Temperature Control Units

- Air Compressors

- Boilers

- Calendar Rolls

- Causitc Lines

- Chill Rolls

- Cooling Towers

- Liquor Tanks

- Pulverizers

- Scrubbers

- Vacuum Pumps

- Air Compressors

- Anthracite Filters

- Boilers

- Condensers

- Converters

- Cooling Towers

- Crackers

- Demisters

- Exchangers

- Flare Drums

- Piping

- Pumps

- Water Heaters

- Air Compressors

- Banbury Mixers

- Boilers

- Calendar Rolls

- Cooling Towers

- Extruders

- Injection Molding Machines

- Mill Rolls

- Molds

- Temperature Control Units

- Throat Coolers

- Towers and Tubers

- Water Heaters

- Air Compressors

- Bearings

- Boilers

- ConCast Units

- Cooling Towers

- Induction Furnces

- Generators

- Heat Exchangers

- Hearth Furnace

- Spangle Units

- Water Heaters

- Air Compressors

- Air Washers

- Boilers

- Condensers

- Cooling Towers

- Extruders

- Heat Exchangers

- Air Compressors

- Banbury Mixers

- Boilers

- Calendar Rolls

- Cooling Towers

- Extruders

- Injection Molding Machines

- Mill Rolls

- Molds

- Temperature Control Units

- Throat Coolers

- Towers and Tubers

- Water Heaters

- Air Compressors

- Boilers

- Cooling Towers

- Heat Exchangers

- Hydrogen Coolers

- Lube Oil Heat Exchangers

- Turbines

- Transformers

- Water Heaters

- Air Compressors

- Boilers

- Cooling Towers

- Heat Exchangers

- Vacuum Pumps

- Vending Machines

- Diesel Generators

- Fire Control Water Systems

- Locomotives

- Potable Water Lines

- Steam Generators

HOW IT WORKS ?

Alpha Descaler is a non-hazardous, non-corrosive, non-injurious, non-toxic, non-fuming, yet fully biodegradable in 10 days acid replacement descaler, heavily fortified with wetting and penetrating agents which actually dissolves water scale, lime, mud, rust, and other water formed deposits from water operated equipment. Alpha Descaler FG is potable water systems and where possible contact with food can occur and for descaling equipment contacting food. It does NOT contain any traditional but often hazardous buffered acids such as hydrochloric, sulfonic, citric, or phosphoric. Here is a full list of specifications for alpha descaler.

TOXICITY – truly non-toxic – note LD50 results on SDS for each product and see articles on toxicity under Resources or click here for SDS

CORROSION TO SKIN AND EYES – not corrosive – see SDS for each product for description

CORROSION TO METALS – metal tests indicate non-corrosive and so low that can be released (under local approvals) directly into the water system after use. See corrosion tests under Resources

GASKETS AND OTHER NORMALLY USED SEALING MATERIALS – traditional acids can react with some rubbers and other material to cause swelling and otherwise negatively affect materials used in sealing. Alpha Descaler does not have negative effects on most materials. See Effect on Sealing materials

SPEED – works as fast or faster than comparative but dangerous mineral acid products. See Video comparing to 12% HCl product.

CAPACITY – regular version equal to comparative but dangerous mineral acid products, extra strength version has double the capacity of regular mineral acids. See Capacity Tests against mineral acid products under Resources

BIODEGRADABILITY – considered 100% biodegradable in under 10 days even at full strength. See Specifications.

DISPOSAL – as per local authorities to obtain approvals but tests have proven material to be marine safe. See Specifications.

FOOD CONTACT – Alpha Descaler FG and Alpha Descaler FG Extra Strength NSF60 approved and has even been in use where food contact is possible.

See NSF60 listing details.

SHIPPING – Alpha Descaler and Alpha Descaler FG, regular and extra strength all have 0-0-0- rating for shipment and considered as non-hazardous material. See Dissolve Rate and Corrosion Rate and Pictogram Comparison to Other Acids

ALL PRODUCTS

-

Alpha Descaler

US $ 175.00 – US $ 1,485.00 Select options This product has multiple variants. The options may be chosen on the product page -

Alpha Descaler Extra Strength

US $ 250.00 – US $ 2,420.00 Select options This product has multiple variants. The options may be chosen on the product page -

Alpha Descaler FG

US $ 160.00 – US $ 1,210.00 Select options This product has multiple variants. The options may be chosen on the product page -

Alpha Descaler FG Extra Strength

US $ 210.00 – US $ 1,650.00 Select options This product has multiple variants. The options may be chosen on the product page -

test product

US $ 1.00 Add to cart

If you need consulting beyond the scope of a complementary sales inquiry, please contact us by email.